decMAtrix® Work Order is a Work Order based decision analysis tool which assists managers and supervisors in the management of Work Order and equipment or asset costs. The product calculates real time costs and variances using a multitude of Work Order Criteria, totals costs and helps with exception management. The tool can also identify equipment with the most hours worked and the most work orders created.

A graphical gantt chart representation of the work order backlog, with multiple scheduling and planning tools.. <more>

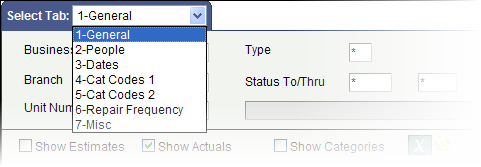

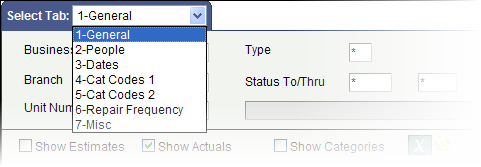

Extensive form and QBE Data Selection criteria for analysis Extensive form and QBE Data Selection criteria for analysis

|

Easy Icon Driven Navigation Easy Icon Driven Navigation

Links to equipment, work order and selective variance analysis functions.

|

Excellent variance analysis functionality Excellent variance analysis functionality

|

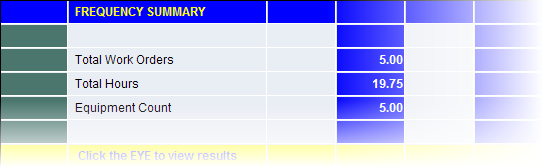

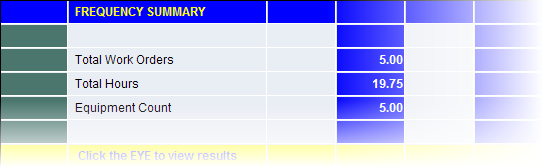

KPI - Repair Frequency summary based on all data selection KPI - Repair Frequency summary based on all data selection

|

KPI - Equipment with most work orders and hours worked on calculation KPI - Equipment with most work orders and hours worked on calculation

This calculation factors in ALL data selection i.e. display the PUMPS in business unit 5540 made by Goulds with the most work orders etc..

Ths KPI also calculates equipment with the most hours:

|

Product Overview.............................................

- For years our clients have asked about a graphical view of the work order backlog - a simple method of getting a quick look at the planned work for the week. We created this tool and then enhanced it with more useful features like multiple work order scheduling and advanced resource and capacity planning.

- This product gives the planner and maintenance manager a unique, graphical view of the work order backlog and allows a seven day planning horizon.

Key Benefits.....................................................

- Graphical view for instant plan assessment

- Instantly see the key resource assigned to each work order

- Quickly reschedule multiple work orders instantly without having to change the scheduled start date on each individual work order.

|

Easy to read visual work view with quick resource check <more>

|

Click here for the key features of this offering. <more> |

|

|

|